CNC Router Cutting Services in Mumbai – Top Cnc Router Cutting Jobworks in Mumbai

CNC (Computer Numerical Control) machining has revolutionized woodworking, offering precision, efficiency, and versatility. Shree Interior Wudtech in Mumbai is a leading name in CNC routing, providing high-quality wood machining services for furniture, interior decor, and custom design projects. Let’s explore the world of CNC machining for wood, its techniques, and its applications.

Can Wood Be CNC Machined?

Yes, wood can be CNC machined with great accuracy. CNC machines use programmed software to cut, carve, and engrave wood, making it a preferred choice for furniture, interior design, and artistic woodwork. With the right techniques and tools, various types of wood can be shaped into intricate designs and patterns.

How Does Wood CNC Machining Work?

CNC wood machining involves automated cutting tools controlled by pre-programmed instructions. The process includes:

- Designing: Creating a digital design using CAD (Computer-Aided Design) software.

- Programming: Converting the design into machine-readable G-code.

- Machining: The CNC router follows the programmed path to cut, carve, or engrave the wood with precision.

- Finishing: Sanding, polishing, and coating for the final look.

What Are the Different Techniques Used in Wood CNC Machining?

Different CNC machining techniques are used depending on the design and material:

- Routing: Cutting complex patterns and shapes.

- Engraving: Creating intricate details on wooden surfaces.

- Milling: Shaping and contouring wood to achieve a smooth finish.

- Drilling: Creating precise holes for joinery and fittings.

- Cutting: Slicing through wood with minimal waste.

What Are Types of Wood for CNC Machining?

Different types of wood are used for CNC machining, including:

- Plywood – Ideal for large-scale furniture projects.

- MDF (Medium-Density Fiberboard) – Great for engraving and detailed work.

- Hardwood (Teak, Oak, Mahogany) – Used for high-quality furniture and decorative items.

- Softwood (Pine, Cedar) – Suitable for general-purpose carvings and designs.

- Plywood Veneers – Used for fine finishing in high-end projects.

How to Use a CNC Machine for Wood: Tips & Tricks

To achieve the best results in CNC wood machining:

- Choose the right cutting tool for the wood type.

- Optimize speed and feed rates to prevent burning or chipping.

- Use a vacuum or clamps to hold the wood firmly.

- Test the design on a scrap piece before final production.

- Maintain sharp and clean cutting bits to ensure precision.

What Are the Tools Required for CNC Machining Wood?

To operate a CNC machine for wood, you need:

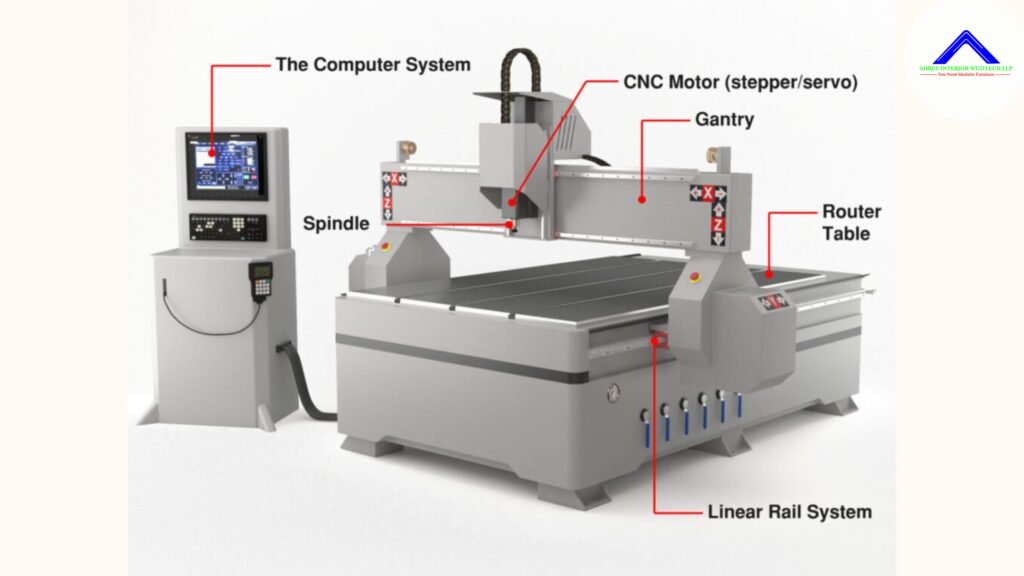

- CNC Router Machine – The primary tool for cutting and carving.

- Cutting Bits & End Mills – Used for different types of cuts and engravings.

- Clamps & Vacuum Tables – To secure the wood during machining.

- Dust Collection System – To keep the work area clean and safe.

- CAD/CAM Software – For designing and converting files into machine-readable formats.

What Are Common Problems and Defects When CNC Machining Wood?

Common challenges in CNC wood machining include:

- Burning & Charring – Caused by high-speed cutting or dull bits.

- Splintering & Chipping – Results from improper feed rates or tool selection.

- Machine Errors – Occur due to incorrect programming or misalignment.

- Inconsistent Depth – Affects engraving and detailed work due to improper calibration.

- Material Warping – Happens due to environmental conditions like humidity.

What Are Applications of Wood CNC Machining?

CNC wood machining is widely used in various industries:

- Furniture Manufacturing – Tables, chairs, cabinets, and decorative elements.

- Interior Designing – Wall panels, moldings, and artistic engravings.

- Signage & Branding – Customized wooden signage and logos.

- Architectural Woodwork – Ornate doors, railings, and frames.

- Handicrafts & Artwork – Personalized gifts, sculptures, and engravings.

How to Choose the Right CNC Technique for Your Project?

Choosing the right CNC technique depends on your project requirements:

- For Detailed Engraving: Use high-precision engraving bits.

- For Large Cuts: Opt for routing with strong end mills.

- For Intricate Designs: Use 3D CNC machining for artistic creations.

- For Heavy-Duty Work: Use multi-axis CNC routers for complex furniture pieces.

- For High-Volume Production: Choose an automated CNC process for efficiency.

Conclusion

Shree Interior Wudtech in Mumbai is your go-to solution for precision CNC wood machining. Whether you need customized furniture, intricate carvings, or high-end interior solutions, our expertise in CNC routing ensures top-quality results. Contact us today for expert CNC machining services tailored to your needs!